- Exploring the Cost of Veneers in South America

- Unveiling the Art of Securing Funding: Yanni Hufnagel’s Pearls of Wisdom for Confident Capital Procurement

- Embark on a Culinary Adventure: Walnut Creek’s Five Must-Try Dining Destinations

- Unlocking the Smile Makeover: A Look at Veneer Costs in Colombia

- Elevating Memory Capacity: Core Approaches to Cognitive Flourishing

The Grand Role of PECVD in Various Industries

January 25, 2017

PECVD’s flexibility and usefulness has propelled it to stardom.

Written by: Denton Vacuum, LLC

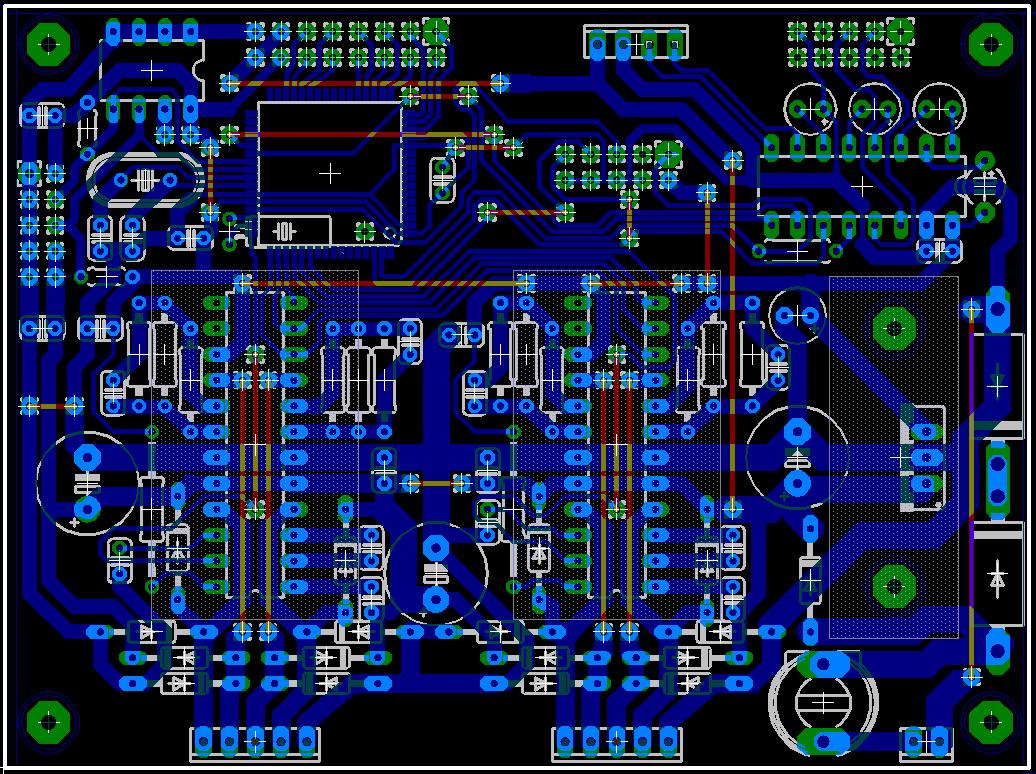

Plasma-enhanced chemical vapor deposition, or PECVD for short, allows for a versatile deposition process. For one, it possesses the ability to create highly uniform thin layers that promote both purity and adhesion, and also allows the user to deposit various types of materials onto the substrate.

Plasma-enhanced chemical vapor deposition, or PECVD for short, allows for a versatile deposition process. For one, it possesses the ability to create highly uniform thin layers that promote both purity and adhesion, and also allows the user to deposit various types of materials onto the substrate.

The Rise of PECVD

PECVD is known for its versatility and efficiency. Many large-scaled industries have found that by using PECVD, they can obtain quality films with outstanding quality. Furthermore, this plasma coating technique has become a staple in a variety of different industries. The outlook on PEVD is nothing short of bright, so expect there to be new technologies popping up frequently and enhancing the field of deposition.

Applications of PECVD

As stated before, PECVD is used in a variety of industries. For instance, the optics industry is known for the manufacturing of optical filter, anti-reflective films, and other similar types of products that utilize a refractive index. The power of PECVD allows for an increase in tool life through the application of wear resistant coatings – such as diamond-like carbon coatings. Another example would be the use of PECVD to prevent corrosion in electronics and microelectronics, which has excelled in terms of technological advancement. You’ll also find the use of PVD coating in the insulation of microelectronics as well as in the production of solar panels. The flexibility and versatility of PECVD are what makes this deposition technology one of the most popular and useful methods in current field today.